Ship's Surgeons as Barbers Page Menu: 1 2 3 4 5 6 7 Next>>

The Ship's Surgeon as BARBER-Surgeon, Page 6

Barbering Instruments: Straight Razor

"A good razor is a rare instrument say many people, but this scarcity often occurs because

Artist: Samuel Van Hoogstraeten - Razor Detail, Tromp-l'oeil (Still-Life) (1667)

one does not sharpen the razor on leather & stone, nor give it a degree of sharpness proportionate to the beard. ...there are thirty bad razors for every four good. " (Jean-Jacques Perret, La Pogonotomie, interpreted by the author, p. 15)

As has already been noted, good razors were very expensive. Much of this cost was due to the high quality steel that was required to get a fine enough edge to create a razor. Rory McCreadie notes that razors could cost more than a sword.1 With this in mind, let's begin with a discussion of metals available to razor-makers in the golden age of piracy.

Barbering Instruments: Straight Razor Steel

A good razor (the sort a barber or surgeon would prefer)

Photographer: Zejo (Wiki Commons)

A

Swedish Walloon Fining Forge Used to Make Wrought Iron.

would be made of high quality steel. At this time there were basically three different kinds of iron-based metals. The first was wrought iron, so named because the steel was worked by hammers or wrought.) Wrought iron contains .02 to .08 percent carbon which makes the metal hard, but still malleable (able to be worked.) This type of metal would be too soft to provide a good edge for a razor.2

The second type of metal was cast iron, which is heated to high temperatures in a blast furnace allowing it to absorb more carbon. Cast iron contains 3 to 4.5 percent of carbon making it very hard, but also very brittle. This type of metal would actually be too brittle to make an effective razor.3

The last type of metal made during the golden age of piracy was steel, which was primarily made at this time by the process of cementation. Steel made by cementation contains 1.5 to 2 percent carbon. This makes it tougher than wrought iron, but less brittle than cast iron. It is still malleable and can be worked. It holds a sharp edge better than the other types of metal.4

Cementation converts wrought iron into steel by sealing it in a fire brick basin in between layers of sifted wood charcoal.

Photographer: Mick Knapton (Wiki Commons)

Cementation Furnace on Doncaster Street in

Sheffield, England

The basin is then heated in a large furnace for 8 to 12 days, allowing the steel to absorb carbon from the charcoal. The resulting bars are called blister steel, because when the material is removed from the furnace, it contains large blisters. This raw material contains a rather uneven distribution of carbon - some parts of the bar are very hard and others are very soft.5

Dr. Andrew Ure explained that, as a result, "in steel works in England, the bars of steel are always broken into several pieces, in order to class those pieces together which are the most similar in quality."6 Ure goes on to reveal:

With regard to the manufactories of cemented or cast steel established upon the Continent, they furnish products the quality of which is so uncertain that the workman is often reduced, after having lost his time and trouble, to throw certain portions away, as they want the necessary uniformity and tenacity.7

The steel could be worked (hammered) to produce a more uniform distribution of the carbon. The upshot is that the material required to hold the fine edge of a razor would be hard to come by, giving an idea as to why the cost of a good razor was so high.

Pouring Crucible Steel Into Ingots, from Popular

Science Monthly, Oct. 1891, p.

739

The big shift in creating better quality steel during this time occurred not long after the end of the golden age of piracy. Benjamin Huntsman started experimenting with methods for making better steels in the 1740s and was eventually able to create a satisfactory cast or 'crucible' steel in Handworth, near Sheffield. This was of better quality than the cementation process-made steel because it was reheated, which created more uniform carbon distribution in the metal. Curiously, the English cutlery companies refused to use it, so he wound up exporting most of his crucible steel to France.8

Like so many things in history, the details of the creation of better steel was not exactly cut-and-dried. Huntsman did not truly invent the crucible steel process. In a discussion on the Authentic Pirate Living History group, Marc Hawtree noted that there is evidence "that small scale 'artisan' production of something similar to crucible steel [was in] use in certain small trades (watch making, surgical instruments, wire drawers, toy makers etc) [which] was available pre-Huntsman"9. Of course, this was on a limited scale suggesting that most, if not all, of the best razors available during the golden age of piracy would probably have been made of steel created by cementation.

1 Rory W. McCreadie, The Barber Surgeon's Mate of the 16th and 17th Century, p. 41; 2,3,4 Joseph S. Spoerl, A Brief History of Iron and Steel Production, www.Anselm.edu, gathered 11/15/13; 5 G. W. Danforth , An Elementary Outline Of Mechanical Processes, p. 90; 6,7 Andrew Ure, A Dictionary of Art, Manufactures, and Mines, 1875, p. 730; 8 Benjamin Huntsman, wikiipedia, gathered 11/15/13; 9 Marc Hawtree, Authentic Pirate Living History, Facebook discussion 10/23/13, gathered 11/15/13

Barbering Instruments: Period Straight Razor Design

Photo: Mission - Razor Terms for a Modern and Golden Age of Piracy Razor

The design of a period razor was akin to that of a jackknife. The handle could be made of various materials such as wood, horn, tortoise shell, or bone. The handle was generally flat, although some were bevelled. The pins in the handle were sometimes brass but generally iron.1

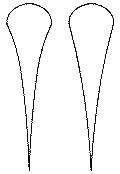

As mentioned, the blade was sharpened all the way to the handle, meaning it had no tang (see diagrams at left). Due to the design, it was impossible to wrap your fingers around any part of the blade without losing

Razor Profiles

Left - Modern Style

Right - Period Style

a finger or two.2 The blade would be wider at the Point than at the blade pivot.

The blade would sometimes have a projection off the back of the handle called a monkey-tail. A near period example of this can be seen in the image at the top of this page. The end of the tang was hammered wide and thin and was shorter than tangs on more modern straight razors.3 This allowed the razor user to open the razor without touching the blade.

The blade itself was wedge-shaped. As was discussed when explaining whether or not men would shave themselves during this period, this created a more challenging profile for the person shaving to handle. The diagram at right shows the period and modern styles of razor blade design. (Note that this is just one of many modern blade styles, but it highlights the difference well.)

1 "Straight Razors - a brief history of their development 1500 – 1820", The Invisible Edge Website, gathered 10/20/13; 2 Rory W. McCreadie, The Barber Surgeon's Mate of the 16th and 17th Century, p. 41-2; 3 Henry T. Lummus, "Old Sheffield Razors", Antiques, December 1922, p. 263

Barbering Instruments: The Razor as a Surgical Tool

Wounded in the Cockpit (1820)

In addition to being used to barber, razors were sometimes used as surgical tools. William Fabry explains that he "never visited my Patients without a Box of Instruments in my Pocket... [which contained]

A Razor."1

Famed French surgeon Ambroise Paré talks about using razors in several different operations including the removal of ganglions2 and the opening of scrotum for treating hernias3. Both operations could be needed at sea.

Naval surgeon John Atkins suggested a razor's use in amputation. As he explains if "you have Limbs so shattered, and hanging only by little Portions of the Muscles, as leaves no Room to hesitate; and these might be smoothed off with a Razor, (less dangerous than the [normal amputation] Operation)"4. Atkins' comment hints that the razor would be used for the sake of convenience and speed, although he later admits that you will get a better stump by doing the amputation properly.

1 Guliielm. Fabritius Hildanus, aka. William Fabry, Cista Militaris, Or, A Military Chest, Furnished Either for Sea or Land, p. 23; 2 Ambroise Paré, The Workes of that Famous Chirurgion Ambrose Parey, p.214; 3 Paré, p. 245; 4 John Atkins, The Navy Surgeon, p. 149